Motivation for cryogenic gas cell

The SHIPTRAP facility at GSI allows for high-accuracy mass measurements of heavy radioactive ions behind the SHIP velocity filter using a double Penning trap system. In 2008 the first ever direct mass measurement of transuranium isotopes c\ould be successfully performed in 252,253,254No with as low as 0.5 ions entering the trap per minute [1,block09]. In order to extend the capabilities of this unique system to heavier ion species with even lower production cross sections, the efficiency of SHIPTRAP has to be increased significantly. Therefore the buffer gas cell of SHIPTRAP will be upgraded, which is currently limited to an overall (i.e. stopping + extraction) efficiency of about 4%. The buffer gas cell, which was built by the LMU group [2,neumayr06a], thermalizes the incoming heavy fusion products in ultra-pure helium (50-100 mbar). Subsequently the ions are guided by electric DC and RF fields to a nozzle at the exit of the gas cell, where they are extracted by the gas flow in a supersonic jet and injected into the acceptance of a subsequent radiofrequency quadrupole (RFQ) designed as ion transport channel and phase space cooler. In this part of the gas catcher the carrier gas is pumped away and the ions gradually enter the high vacuum regime.

So far the efficiency of the buffer gas cell at SHIPTRAP was limited by several constraints: due to space restrictions the injection into the cell had to be performed almost perpendicular to the extraction axis, requiring an accurate stopping of the incoming ionson the central axis, which is specifically difficult in view of the large beam dimensions behind SHIP with a beam diameter of at least 60 mm. Moreover, severe purity requirements for the buffer gas inside the stopping chamber had to be fulfilled in order to minimize ion losses due to charge exchange reactions. Here in the past several intrinsic gas contamionations (especially from Xenon isotopes) had to be removed via the use of a liquid-nitrogen filled cryotrap in the gas feeding line at the entrance to the gas cell.

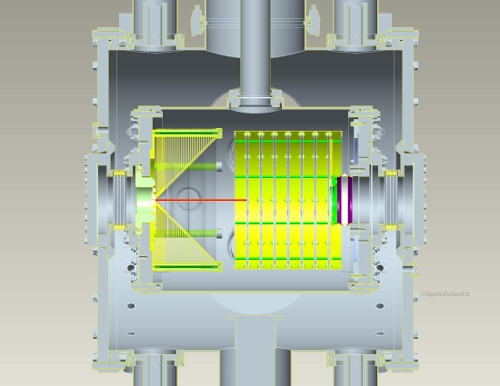

A significant increase of the stopping and extraction efficiency can be expected when using a cryogenic gas cell, where the low temperature (about 40 K) will inherently ensure the purity of the helium gas by freezing out of impurities, while allowing at the same time to operate the gas cell at a higher helium density, equivalent to a higher gas pressure as presently available at the room temperature system. Cryogenic operation also allows for a wider choice of materials inside the gas cell compared to an ultra-high vacuum compatible system, e.g. in future not all electrical contacts will have to be fed individually into the vacuum chamber, which in the past reperatedly caused problems by leakages occurring at the sensitive ceramic multi-pin feedthrough connectors. Instead in the cryogenic case electronic circuits (like voltage dividers) will be allowed also inside the vacuum chamber. While the design of the cryogenic vacuum chamber is performed by the GSI group, the interior part of the stopping cell with its electrode system has been designed under the responsibility of the LMU group. The figure shows the complete view of the cryogenic gas cell design.

Design of the cryogenic gas cell for SHIPTRAP with the cold inner part of the gas cell, isolated by an outer evacuated vessel. The inner part carries the extraction electrode system: the metallic entrance window, the segmented DC electrodes, the RF funnel and the extraction nozzle.