Present Setup of SHIPTRAP

Content

Overview of SHIPTRAP facility

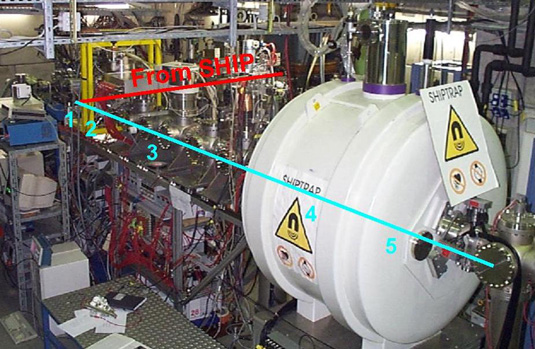

SHIPTRAP is a double Penning ion trap system for high-precision mass measurements of transuranium recoil-ions from the SHIP facility at GSI.

The system consists of a buffer-gas cell (1) to thermalise the incoming ions, an extraction system (2) to separate the ions from the buffer gas, an RFQ buncher (3) to cool and accumulate the ions and a tandem Penning-trap system for isobaric purification (4) and high-precision mass measurements (5). The buffer-gas cell and the extraction RFQ were developed, assembled and tested at the MLL (Maier-Leibnitz Laboratory) in Garching and at the GSI.

The energy of the reaction products will vary between 0.1 and 1 MeV/u.

The gas stopping cell setup

The contribution of the LMU group to SHIPTRAP is the central component of the buffer gas stopping cell and the subsequent extraction radiofrequency quadrupole.

The main requirements given for the gas-cell/extraction-RFQ system are a fast and effective extraction of the stopped recoil ions. Therefore besides the purity of the system preventing recombination and molecule formation, ensured by the use of only non-organic material inside the cell and a highly efficient gas purification, especially the interaction between guiding electric fields and the gas flow inside the system has been optimised. The design optimisation of the different parts of the system was achieved using simulation programs like the VARJET code (gas flow), the SIMION code (ion trajectories in electric fields), a combination of both and the SRIM code (stopping ranges of ions in matter).

In the actual set-up of buffer-gas cell/extraction-RFQ the ions enter the cell through a thin metallic entrance foil (~4 µm thick, Ø 60 mm) and are stopped in the helium buffer gas (~50 – 200 mbar). The thermalised ions are then accelerated by electric fields (~10 V/cm) created by a segmented DC electrode inside the gas cell towards a funnel-shaped ring electrode structure. This funnel guides the ions by the applied RF and DC fields towards the extraction nozzle (Ø 0.6 mm) which acts as an interface between the stopping chamber and the extraction chamber. At the nozzle the buffer gas expands into the extraction chamber (10-1 – 10-3 mbar) creating a supersonic gas jet and dragging the extracted ions. Inside the extraction-RFQ structure the ions are separated from the buffer gas and are cooled during the transport. In order to guarantee an optimum purity, the set-up is bakeable and a hydrocarbon-free pumping equipment is used.

Buffer-gas cell components

After passing through the entrance window the ions are thermalised inside the stopping chamber. An electrode system generating DC and RF fields inside the chamber guides the ions towards the extraction nozzle. Here the ions are transported into the extraction chamber via the gas flow. The extraction RFQ following the nozzle is used for separating the ions from the neutral gas and for cooling the ions transversely for the transfer into the RFQ buncher .

Electrodes

The electrode system in the SHIPTRAP gas cell has to guide the ions towards the nozzle. Two different types of electrodes are used, an exclusive DC electrode for the ion acceleration and the focussing funnel structure using DC and RF fields.

Extraction nozzle

The nozzle provides the transition between the high-pressure area inside the cell and the low-pressure region in the extraction chamber. The shape of the nozzle was optimised with gas-dynamical simulations using the code VARJET.

The nozzle throat has an inner diameter of 0.6 mm and both sides of the nozzle throat have a conical shape. The convergent nozzle entrance starts with an open diameter of 2 mm and an angle of 90°. It was optimised to achieve subsonic gas velocities high enough to drag the ions through the nozzle. The divergent nozzle exit ends in a diameter of 6 mm with an angle of 38°. The shape was optimised to perform a supersonic gas jet for an effective transfer of the ions into the extraction RFQ and an effective transversal cooling within the first RFQ segments.

Extraction RFQ

The main purpose of the extraction system is the separation of the ions from the neutral buffer gas and the transverse cooling of the ions. A segmented RFQ is used to be able to apply a DC ramp in order to compensate for the damping by the buffer gas inside the extraction chamber.

Status

The SHIPTRAP facility is routinely and successfully running mass measurements since 2006. A typical overall efficiency of 1% is reached for ions entering the gas cell up to their injection into the Penning trap system. With this efficiency mass measurements down to nuclear reaction cross section of 200 nb became possible, leading in 2008 to the first-ever direct mass measurement of transuranium isotopes (252,253,254No).

This milestone in trap-based nuclear mass measurement of unstable ions was published in Nature & Science:

- M. Block et al, Direct mass measurements above uranium bridge the gap to the island of stability, Nature 463, 785 (2010)

- E. Minaya Ramirez et al., Direct mapping of shell-effects in the heaviest elements, Science 337, 1207 (2012).

In order to upgrade the SHIPTRAP system by increasing the transmission efficiency , thus enabling measurements with significantly lower production cross sections, presently a novel cryogenic buffer gas cell is under constrruction. The LMU group contributes the innermost sections of the gas cell with the metallic, isolated entrance window, the DC electrode system, the RF funnel and the extraction nozzle.